|

|||||||

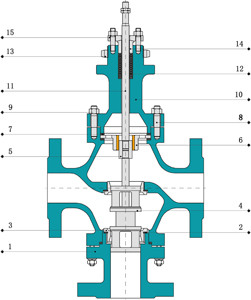

| 1 | 閥體Body | WCB | LCB | WC9 | CF8 | CF8M | CF3M |

| 2 | 墊片Shim | 316+石墨Graphite / FTFE | 316+石墨Graphite / FTFE | ||||

| 3 | 閥座Seat | 304 | 304 | 304 | 304 | 316 | 316L |

| 4 | 閥芯Spool | 304 | 304 | 304 | 304 | 316 | 316L |

| 5 | 連接器Connector | 304 | 304 | 304 | 304 | 316 | 316L |

| 6 | 導(dǎo)向套Guide sleeve | 304 | 304 | 304 | 304 | 316 | 316L |

| 7 | 墊片Shim | 316+石墨Graphite / FTFE | 316+石墨Graphite / FTFE | ||||

| 8 | 螺柱Stud | 304 | 304 | 304 | 304 | 316 | 316L |

| 9 | 螺母Nut | 304 | 304 | 304 | 304 | 316 | 316L |

| 10 | 閥蓋Valve cover | WCB | LCB | WC9 | CF8 | CF8M | CF3M |

| 11 | 閥桿Valve stem | 304 | 304 | 304 | 304 | 316 | 316L |

| 12 | 填料Packing | PTFE / 柔性石墨 | PTFE / 柔性石墨 | ||||

| 13 | 鎖緊螺母Lock nut | 304 | 304 | 304 | 304 | 316 | 316L |

| 14 | 壓套Pressing ring | 304 | 304 | 304 | 304 | 316 | 316L |

| 15 | 壓板Plate | 304 | 304 | 304 | 304 | 316 | 316L |

| The above parameters for the standard configuration, soft seal can be specially made to order 6 seal. Valve inner part capable of providing spray welding hard alloy. Conventional materials for carbon steel and stainless steel two, according to the user site conditions custom special material control valve products. |

|||||||

| dn(mm) Inside diameter(in) |

25 1 |

32 1-1/4 |

40 1-1/2 |

50 2 |

65 2-1/2 |

80 3 |

100 4 |

125 5 |

150 6 |

200 8 |

250 10 |

300 12 |

||

| (KV) Flow coefficient | 8.5 | 13 | 21 | 34 | 53 | 85 | 135 | 210 | 340 | 535 | 800 | 1280 | ||

| (DN) (in) |

Travel | Optional flow coefficient CV (★ Standard type ● Recommend) | ||||||||||||

| 25 1 | 16 mm | ★ | ||||||||||||

| 32 1-1/4 | 25 mm | ★ | ||||||||||||

| 40 1-1/2 | ● | ★ | ||||||||||||

| 50 2 | ● | ● | ★ | |||||||||||

| 65 2-1/2 | 40 mm | ★ | ||||||||||||

| 80 3 | ● | ★ | ||||||||||||

| 100 4 | ● | ● | ★ | |||||||||||

| 125 5 | 60 mm | ★ | ||||||||||||

| 150 6 | ● | ★ | ||||||||||||

| 200 8 | ● | ● | ★ | |||||||||||

| 250 10 | 100 mm | ● | ● | ★ | ||||||||||

| 300 12 | ● | ● | ★ | |||||||||||

| 氣動執(zhí)行機(jī)構(gòu) Pneumatic actuator |

HA/B-23 | HA/B-34 | HA/B-45 | HA/B-56 | ||||||||||

| 350 cm2 | 560 cm2 | 900 cm2 | 1400 cm2 | |||||||||||

| Mode of action | Spring range | Metal seal allows differential pressure (Mpa) | ||||||||||||

| Gas opening | 20-100Kpa | 0.7 | 0.44 | 0.28 | 0.18 | 0.17 | 0.11 | 0.07 | 0.07 | 0.05 | 0.03 | 0.05 | 0.03 | |

| 40-200Kpa | 2.14 | 1.31 | 0.84 | 0.53 | 0.51 | 0.33 | 0.21 | 0.22 | 0.15 | 0.09 | 0.11 | 0.07 | ||

| 80-240Kpa | 4.99 | 3.05 | 1.95 | 1.25 | 1.18 | 0.78 | 0.5 | 0.51 | 0.36 | 0.21 | 0.21 | 0.15 | ||

| Gas off | 20-100Kpa | 2.14 | 0.87 | 0.56 | 0.35 | 0.34 | 0.22 | 0.14 | 0.15 | 0.1 | 0.06 | 0.05 | 0.03 | |

| 40-200Kpa | 6.4 | 5.86 | 3.64 | 2.3 | 2.21 | 1.43 | 0.91 | 0.95 | 0.66 | 0.37 | 0.11 | 0.07 | ||

| 80-240Kpa | 6.4 | 6.4 | 5.04 | 3.18 | 3.06 | 1.98 | 1.26 | 1.32 | 0.92 | 0.52 | 0.21 | 0.15 | ||

| Electric actuator | Metal seal allows differential pressure (Mpa) | |||||||||||||

| Thrust(N) | 800 | 1.52 | ||||||||||||

| 2000 | 3.05 | 1.86 | 1.19 | 0.76 | ||||||||||

| 3000 | 2.79 | 1.79 | 1.14 | 1.13 | 0.6 | |||||||||

| 5000 | 4.66 | 2.98 | 1.91 | 1.35 | 0.8 | 0.47 | ||||||||

| 6500 | 0.57 | 0.39 | 0.26 | 0.16 | ||||||||||

| 10000 | 0.61 | 0.42 | 0.20 | 0.17 | 0.11 | |||||||||

| 16000 | 0.97 | 0.67 | 0.35 | 0.27 | 0.18 | |||||||||